How Hospital Supply Chain Leaders Can Thrive in a Virtual Environment

COVID-19 has created countless challenges across every industry, and healthcare facilities have been especially hard-hit. According to some estimates, the demand for PPE at hospitals increased by as much as 1700% in the early months of the pandemic. U.S.-based manufacturers were unprepared to meet such a steep spike in demand, and much of the country’s PPE supply had to come from China. In addition, there were widespread shortages of other vital equipment.

The shortages had a significant impact not only on providers and staff at healthcare facilities, but on supply chain leaders within these organizations as well.

How COVID-19 has affected supply chain leaders

Hospital supply chain leaders have a demanding role. They help determine which equipment and supplies staff prefer, negotiate contracts, and manage those contracts closely to ensure they are spending their budget wisely. They also must forecast demand to ensure their facilities are well-stocked with the equipment and supplies providers and staff need to do their jobs safely and effectively.

“One of the biggest challenges facing healthcare supply chain leaders we work with is visibility across a health system, or even within individual facilities,” said Austin Dirks, CEO and founder of GreenLight Medical. “More than ever before, hospital teams need to be able to quickly assess product decision-making within the system, product usage and associated financial impact across the board.”

The shortages caused by COVID-19 have forced supply chain leaders to plan further ahead with a unclear picture of the horizon. Many hospitals are likely to experience the same shortages at once, which means supply chain leaders can’t rely on being able to fulfill a last-minute order if there is a disruption in the facility’s supply chain.

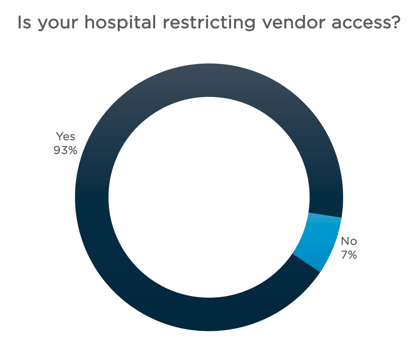

Hospital supply chain leaders also have to navigate more complex disease-prevention guidelines to ensure that no vendor compromises the health and safety of staff, providers, and patients. In a recent symplr survey of healthcare supply chain leaders, 93% said they are restricting vendor access to their facilities due to COVID-19. Of those restricting vendor access, 88% are only allowing access to specific vendors or functions, deemed as essential, and 12% are not allowing vendors to enter their facilities at all.

Access challenges are unlikely to be resolved any time soon. Eighty percent of supply chain leaders who have restricted vendor access to their facilities expect to continue to do so for at least the next three months, or until a COVID-19 vaccine has been identified and widely distributed. It should come as no surprise, then, that hospital leaders surveyed since COVID-19 hit the U.S. have consistently ranked supply chain management and optimization as their second-highest priority, after virtual care.

How hospital supply chain leaders can adapt to the new reality

Hospital supply chain leaders must adjust to this more challenging environment to effectively do their jobs. The question is: How? These steps are a great place to start.

1. Create a plan to address current and future bottlenecks in the supply chain

The top priority for hospital supply chain leaders should be to address and mitigate existing bottlenecks and shortages in the supply chain. There are a number of ways to address this issue, including:

- Pooling resources across facilities in a group

- Identifying alternate vendors to meet the immediate need on a short-term basis

- Collaborating with other individual hospitals to address supply chain issues

Creating a plan to address existing bottlenecks is crucial at this juncture, but hospital supply chain leaders should also take this opportunity to extrapolate potential future shortages or bottlenecks based on existing shortages.

For example, if a shortage of ventilators is expected in the near future, supply chain leaders not only should have a plan for a shortage of ventilators, but also for a likely future shortage of oxygen tanks and sedatives, both of which are necessary for ventilator use.

2. Simplify your supply chain

The more unique links there are in a supply chain, the more difficult it is for hospital supply chain leaders to track each supplier’s status to accurately forecast short- and long-term needs. Where possible, supply chain leaders should consider simplifying their facility’s supply chain—especially now, when the Centers for Disease Control’s guidelines are more complex.

No part of the supply chain is a standalone process, and dependencies such as restrictive contracts, market conditions, and changing organizational needs present complexities. But integrated planning and comprehensive data analysis can aid in simplification wherever possible.

3. Do as much as you can virtually

“Shifting to a virtual supply chain model is a difficult concept to consume, as tangible supplies will always be a part of this industry. But by structuring tools around virtualization, supply chain teams ensure a health check on their own health system—[a need] which is especially evident in recent months with urgency around COVID-19 demand planning. [It can be] done from a remote setting. Technology-enhanced supply chain means a 24/7 assessment for all stakeholders,” said Dirks.

Now more than ever, a proper vendor credentialing system is vital for supply chain leaders. Leaders should restrict vendor access until they can virtually communicate their facility’s COVID-19 policies and confirm that vendors are following the policies. By the same token, supply chain leaders should ask their vendors to inform the facility if any vendor representative tests positive for COVID-19.

How technology solutions help supply chain leaders

To meet modern challenges, hospital supply chain leaders need to rely on technology solutions. Many organizations outside of the healthcare industry have turned to demand forecasting technology for help in predicting future shortages. However, given the unique nature of their supply chain, healthcare facilities don’t have the luxury of employing software specifically for this purpose.

“Looking to the future of supply chain management, we believe there will be a hybrid model where collaboration, decision-making, process, and policy will all be enabled by technology and not physical presence,” explained Dirks. “Technology solutions are what will enable supply chain leaders to maintain compliant virtual and physical access to healthcare facilities, for both the vendor and vendor’s product, to guarantee verified and protected entry of products into the supply chain.”

Technology solutions leveraging predictive analysis and/or business insight tools can help supply chain leaders more accurately predict the future needs of their facilities. When used in concert with value analysis solutions, supply chain leaders can more easily identify long-term needs, share the information with key stakeholders, and simplify the process of addressing those needs with vendors — all in a virtual environment.

Hospital supply chain leaders must adjust and adapt their processes to meet the challenges of COVID-19, and virtual solutions will play a key role in that evolution in the months to come. With proper planning and the support of modern technology solutions, supply chain leaders can help ensure their facilities are prepared for whatever comes next.